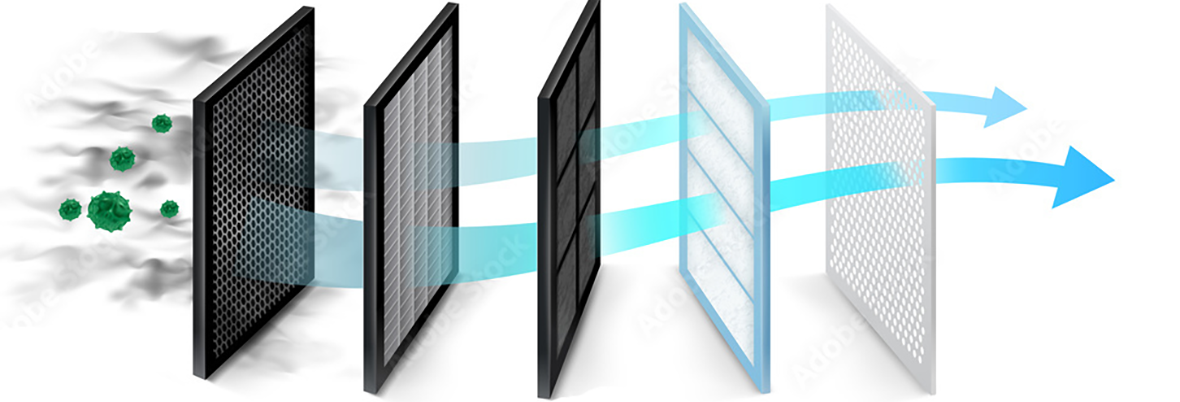

Air filter performance test methods

The Aerosol Technology Research Group (ATRG) takes active part in the development of international air filtration test methods. We contribute to develop documents published by ISO, CEN, ASHRAE, etc. to continuously improve the reliability, repeatability and reproducibility of existing and future test methods.

ATRG is an active participant in inter-laboratory studies aimed to validate experimental procedures and assess the meaninfulness of data obtained in laboratory. One of our most important goals is to pursue a better correlation between laboratory data and actual operating performance of air cleaning devices and technologies.

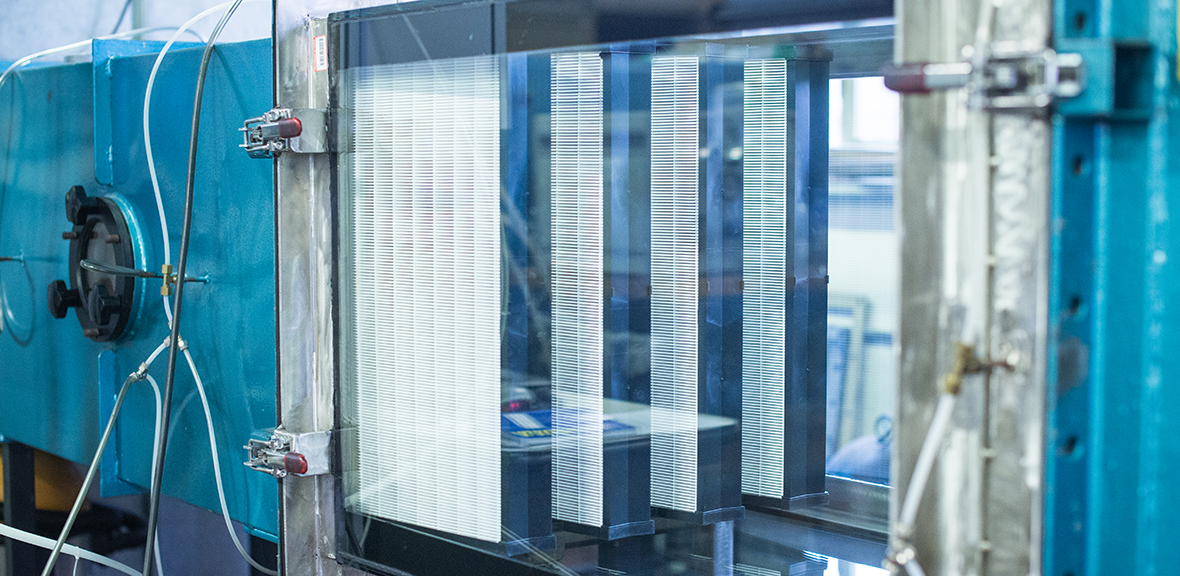

Energy implications of air filtering elements

Air filtering elements have a remarkable contribution to the energy consumption of modern air conditioning systems. Thus, it is important to study their lifetime impact on the power requirements for different applications in order to develop more efficient and sustainable filtering components and HVAC systems through a better understanding of the implicated phenomena. For these reasons, the Politecnico di Torino’s Aerosol Technology Research Group conducts ongoing studies aimed to determine more realistic air filter testing approaches, based on the assessment of the in-situ behavior of HVAC filters and the correlation with the results obtained in laboratory tests following the Eurovent 4/21 recommendation.

This continuous activity has allowed to collect years of data about several air quality and air conditioning system parameters, that allowed to improve the management schemes of the Polytechnic’s HVAC plants and gain a better understanding of their energy requirements.

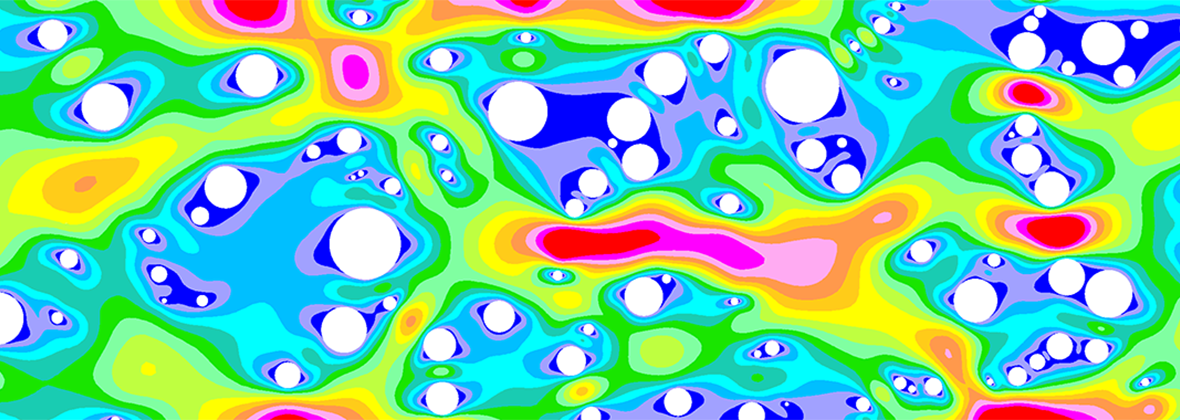

Numerical simulation of fibrous air filtration media and devices

At the moment, laboratory procedures are still the preferred method to provide data about air filter performance assessment. Nevertheless, both efficiency and service life, with associated energy costs, are not completely understood and cannot be simulated in laboratory with general validity, due to the huge variability of the operation of fibrous air filters. For these reasons, the accurate prediction of the performance of fibrous air filter media from basic considerations – the geometry of the fiber mat and the characteristics of the gas flowing through it – is one of the goals pursued by ATRG. The availability of reasonably accurate models would allow to cover a much wider spectrum of applications and ultimately could provide much more meaningful and useful data, both for manufacturers and end users.

Face mask filtration performance

At the moment, laboratory procedures are still the preferred method to provide data about air filter performance assessment. Nevertheless, both efficiency and service life, with associated energy costs, are not completely understood and cannot be simulated in laboratory with general validity, due to the huge variability of the operation of fibrous air filters. For these reasons, the accurate prediction of the performance of fibrous air filter media from basic considerations – the geometry of the fiber mat and the characteristics of the gas flowing through it – is one of the goals pursued by ATRG. The availability of reasonably accurate models would allow to cover a much wider spectrum of applications and ultimately could provide much more meaningful and useful data, both for manufacturers and end users.

Low-cost particulate matter (PM) sensors

At the moment, laboratory procedures are still the preferred method to provide data about air filter performance assessment. Nevertheless, both efficiency and service life, with associated energy costs, are not completely understood and cannot be simulated in laboratory with general validity, due to the huge variability of the operation of fibrous air filters. For these reasons, the accurate prediction of the performance of fibrous air filter media from basic considerations – the geometry of the fiber mat and the characteristics of the gas flowing through it – is one of the goals pursued by ATRG. The availability of reasonably accurate models would allow to cover a much wider spectrum of applications and ultimately could provide much more meaningful and useful data, both for manufacturers and end users.